DynaSil™-Formula Free

DynaSil™ uniquely enables traditional halogen and non-halogen flame retardants to work more effectively.Small additions of DynaSil™ can reduce heat release rates, reduce smoke generation, eliminate or minimize traditional harmful flame retardant chemicals, improve processing, and increase elongation for highly loaded compounds.using DynaSil™ in your formulations can provide more creative solutions in flame retardant applications.

DynaSil™ uniquely enables traditional halogen and non-halogen flame retardants to work more effectively.Small additions of DynaSil™ can reduce heat release rates, reduce smoke generation, eliminate or minimize traditional harmful flame retardant chemicals, improve processing, and increase elongation for highly loaded compounds.using DynaSil™ in your formulations can provide more creative solutions in flame retardant applications.

elimination of antimony

replaces antimony in PVC

replaces antimony in PVC

* 100% replacement of antimony based on activity

DynaSil™ technology provides:

- antimony substitution

- Improve overall fire performance

- heat release rate

- Smoke Reduction

- better charring formation

- reduce the need for flame retardants

- improve elongation

- easy to handle

- has no regulatory issues

- -Friendly Eco-Toxins

DynaSIl™ works

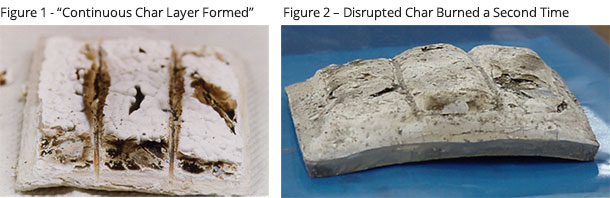

DynaSil™ provides a unique approach to flame retardancy. When DynaSil™ burns, it forms a thin glass barrier that holds the halogen or active flame retardant in the matrix for maximum efficiency. When the fire is extinguished, the material flows to the oxygen-rich surface and quickly crystallizes to form a strong carbon layer, which will block the fuel source and prevent the polymer from reigniting. Even if the DynaSil™ remains in the matrix after combustion, the second combustion causes the DynaSil™ to flow to the exposed area and re-form solid char, preventing further combustion.

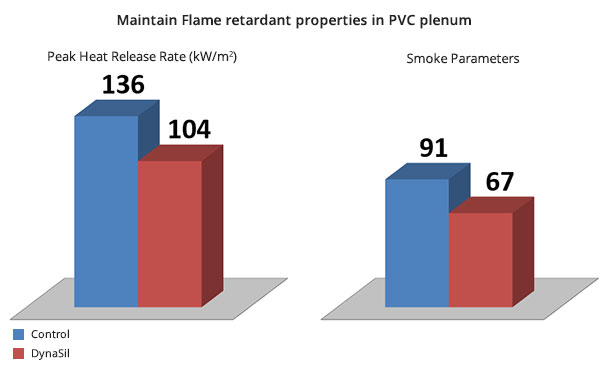

Reduces smoke generation without the use of metal salts or AOM

To demonstrate the added benefit of DynaSil™, AOM (ammonium octamolybdate) has been removed from the Plenum formula in favor of DynaSil™. The control and replacement samples were then sent to an external laboratory for evaluation in a cone calorimeter. These results not only demonstrate that Dynasil™ is a successful replacement for AOM, it also reduces peak heat release, lowers smoke parameters, and improves fire performance index.

Antimony Removal from Polyamides and Other Engineering Plastics

Dynasil™ effectively eliminates the need for antimony or reduces the amount of antimony required for most engineering plastics, while improving other properties. Evaluation of different loadings of DynaSil™ in polyamide 6,6 showed that Dynasil™ was still effective at half the level of antimony activity.

replacement of antimony in polyamide 6,6

Improving LSZH Performance with DynaSil™

use DynaSil™ to improve LOI and balance mechanical properties. To demonstrate this improvement, we used a simple low-smoke zero-halogen formula, filled with 60% magnesium hydroxide polypropylene, and added 5% Dynasil™. The result was a mere 38% increase in LOI.

In order to evaluate the effect of DynaSil™ on mechanical properties, a 50% load system was evaluated, and various loads of DynaSil™ were evaluated to see the effect on stretch and elongation. DynaSil™ does have a negative impact on tensile strength, while elongation increases to 94% as the load level increases.using DynaSil™ with a low 5% load.

DynaSil™ is a unique tool that can be used to formulate flame retardant compounds with previously unachievable properties. Although the above properties show drastic changes, this is a very simple system that only contains resin, flame retardant and DynaSil™. Using DynaSil™ as a tool in the formulation system can easily solve the tensile loss and can also significantly increase the elongation. Our DynaChar compounds utilize DynaSil™ technology to provide systems with LOI greater than 43, elongation greater than 150 percent, and tensile strength greater than 1750PSI.