engine components

can cost-effectively produce functional engine parts with complex geometries and specified characteristics-even in small series production.

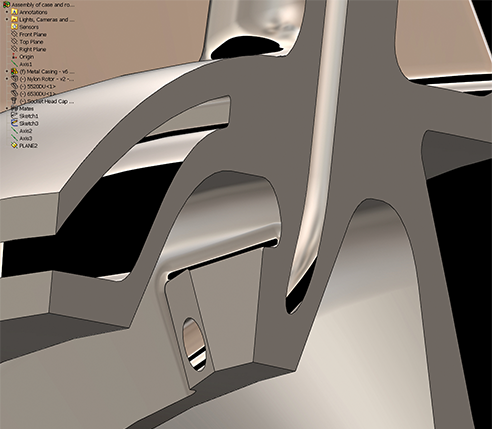

additive manufacturing (AM/industrial 3D printing) are reflected in the production of engine and turbine parts, even in small batches. Functional parts with demanding geometry requirements and specified aerodynamic or hydrodynamic characteristics can be produced quickly and economically using EOS laser sintering equipment. Functional parts include the fuel system, guide vanes and turbine blades, additional systems and special thermal protection components. Even very complex parts made of high-strength materials, which may contain cavities or tubing, can be easily produced using EOS additive manufacturing technology, which may not be possible or very expensive to produce using traditional manufacturing processes.

In addition, EOS additive manufacturing technology can also be used to develop advanced lightweight designs that not only increase strength, but also reduce weight by up to 60%. The use of these innovative components reduces fuel consumption and CO2 emissions. This design helps to significantly reduce the environmental impact of the aircraft throughout its life cycle.

Additive Manufacturing in Practice-EOS Aerospace Case Study, Additive Manufacturing in Practice-EOS Aerospace Case Study

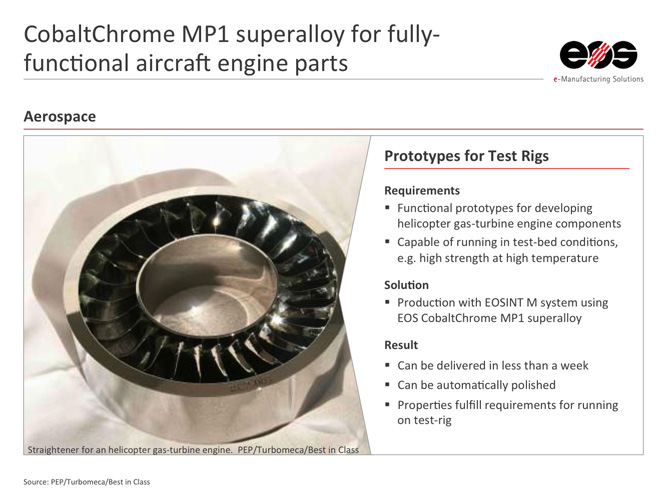

test bench prototype-cobalt-chromium MP1 super alloy, suitable for fully functional aircraft engine parts

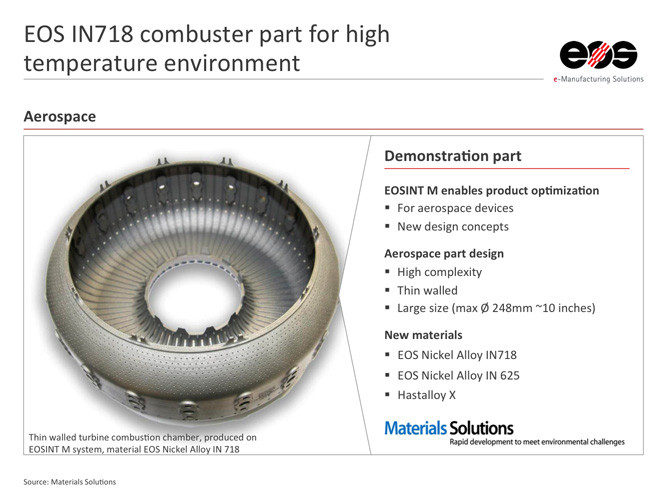

demonstration part-EOS nickel-based alloy 718 combustion chamber parts, suitable for high temperature environment

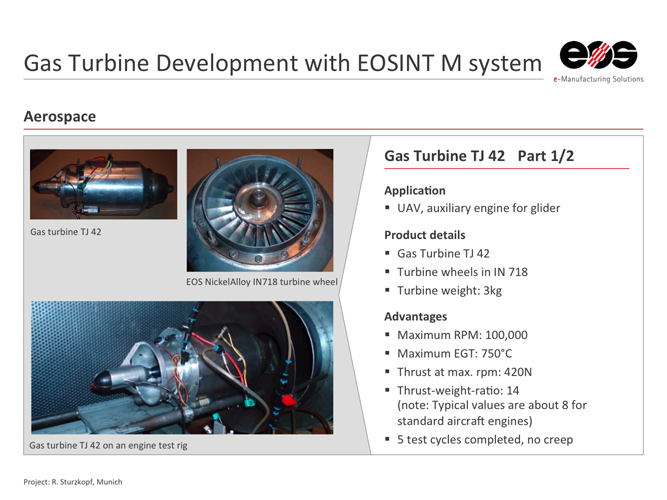

Gas Turbine TJ 42-Gas Turbine Development Using EOSINT M Metal Equipment (2 slides)