3D Printing for Unmanned Aerial Vehicles (UAVs)

EOS additive manufacturing technology can greatly improve the design flexibility, which is the ideal production method for rapid prototyping and small batch production.

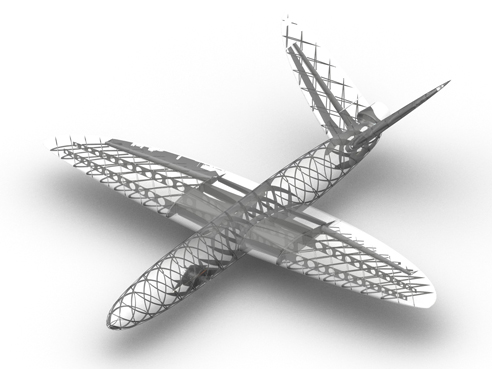

Cost-effective prototyping and low-volume production play an important role in the rapidly growing unmanned aerial vehicle (UAV) market. This is an ideal area for additive manufacturing (AM): even one-off parts do not incur additional costs in the production process, and EOS technology is very suitable for rapid prototyping (RP) and small batch production. Users can develop variants without incurring additional tooling costs. This saves money and minimizes risk. The innovative EOS additive manufacturing process offers great design freedom to product engineers. Even complex aerodynamic structures can be manufactured economically and quickly based on CAD (Computer Aided Design) data. A movable part such as a flap or a hinge can be easily integrated into a wing or fuselage in one production operation.

from design sketch to first flight in a month

Another advantage of additive manufacturing is the rapid availability of products: the University of Southampton completed the development and manufacture of the "SULSA" drone in less than a month. Production is based on EOS additive manufacturing technology and was completed by 3T RPD in one week. The entire fuselage, including the wings and empennage, consisted of only five components, with simple snap-on connectors. In its first flight, the drone showed excellent aerial capability.