EOS Additive Manufacturing in the Field of Racing Components

racing has been the think tank of the automotive industry for decades. New ideas and technologies can be put into practice in racing before they are put into mass production. A large number of components used in racing are custom pieces. In addition to precisely defined functional characteristics, low weight and high stability are often key requirements. This places considerable demands on the manufacturing processes used: such processes must enable innovative and often unusual designs, but also support the production of parts and part design changes in as simple and cost-effective a manner as possible.

EOS additive manufacturing technology perfectly fits these requirements. This technology provides design engineers with the necessary flexibility to transform innovative ideas into high-performance products, sometimes for highly complex designs, which only involve the application of materials for the required functions, so that the resulting components are light and rigid, taking into account integrated functions when necessary.

Because there is no need to rely on molds when using additive manufacturing, design engineers can gain a higher degree of freedom when designing data and perform physical verification in a short time. More importantly, users can use a wide variety of materials: EOS provides a high quality of metal and plastic materials with various characteristics. It is because of these advantages that so many racing teams use EOS additive manufacturing technology.

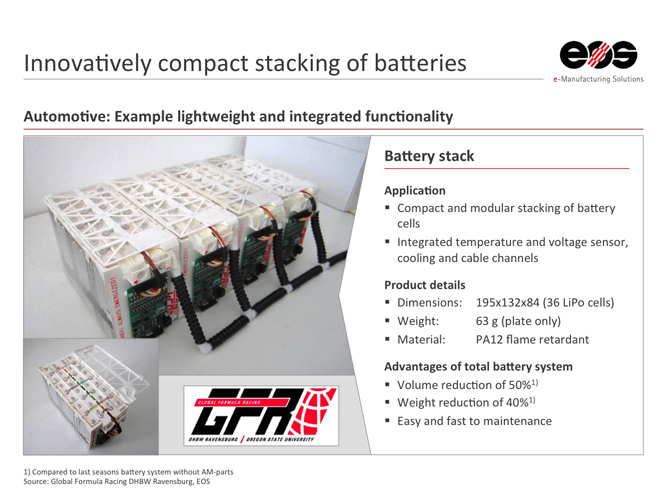

international cooperation: Global Formula Racing's racing car is the first and only electric car designed and built by German and American university students

(Source: Global Formula Racing).

young engineers win with EOS

additive manufacturing can produce components with integrated functions-no tools are required, so development and production costs are cut. In addition, suppliers can meet customer requirements by providing personalized parts for mass production.

Through rapid prototyping design based on additive manufacturing, automakers can improve their research and development efficiency and bring their products to market faster. In addition to pursuing the accuracy of the geometric shape of parts, EOS is also continuously expanding the scope of its new materials to ensure that the parts are of the same functional quality and can be directly installed on mass production vehicles.

Practice-EOS Aerospace Case Study

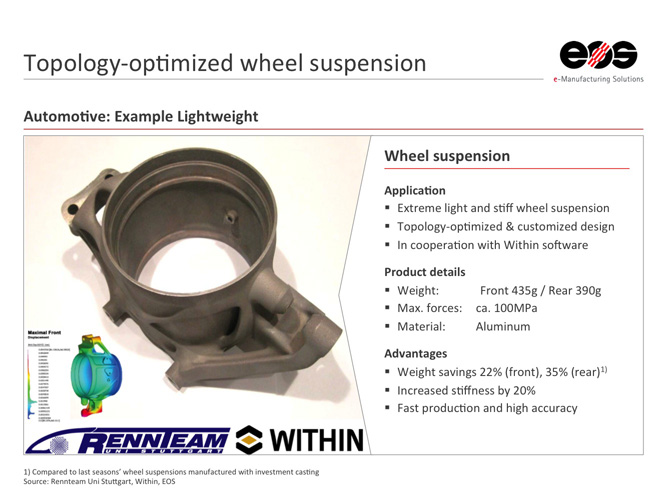

Wheel Suspension-Topology Optimized Wheel Suspension

drive shaft-innovative drive shaft design reduces weight by more than 70%

battery pack-original compact battery pack design