3D application industry-mold

industrial-grade 3D printing technology for molds-functional processes to get back faster.

EOS additive manufacturing can not only improve the productivity of the mold and improve product quality

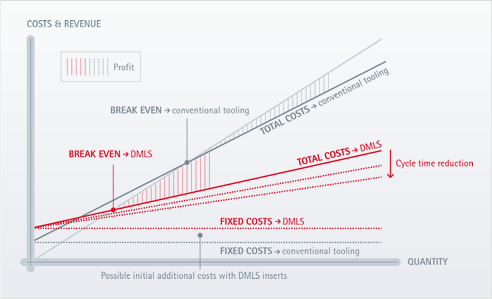

In many industries, the production of professional molds is one of the most expensive aspects of the production process. Production using traditional processes is often costly, time-consuming and technically demanding. The EOS solution is based on additive manufacturing, which enables faster manufacturing of individual parts or personalized batch products, while also increasing cost efficiency and flexibility-even in small batches.

For additive manufacturing, highly complex shapes and designs such as integrated cooling or heat dissipation channels are not a problem. Traditional production processes have reached the limits of their capabilities: they limit design and manufacturing freedom, for example, the only cooling solution is often to drill holes in the required channels. Moreover, with the increasing complexity of the mold, the corresponding cost will also rise.

The design advantages of EOS additive manufacturing can improve both mold productivity and product quality. Scrap rates and individual component costs will also fall. In addition, manufacturers can benefit from shorter production cycles and longer tool life. Moreover, by adopting additive manufacturing technology, they can also speed up the time to market. For example:Innomia uses additive manufacturing instead of traditional molding technology as a mold optimization project, it successfully reduced the time to market from 18 days to 13 days.

Advantages of using additive manufacturing for molding

• Maximize design freedom• Enables design-driven manufacturing

• Improve mold efficiency and get returns faster

• Flexible machining process, e.g. hybrid manufacturing process/non-hybrid manufacturing process can be selected

• Functional integration

• Independent process to reduce labor costs

EOS can also help companies achieve their sustainability goals: in short, additive manufacturing can improve production efficiency, speed up production and reduce scrap rates. The ultimate reduction in CO2 emissions.

Partner Application Cases

FADO is a mould and injection moulding company founded in 1984 and headquartered in Bydgoszcz, Poland. FADO is one of EOS's official service providers in the field of DMLS (Direct Metal Laser Sintering). EOS additive manufacturing technology enables FADO to manufacture inserts with conformal cooling channels, which can shorten the production cycle by an average of 30% and improve the overall quality of injection molded parts.